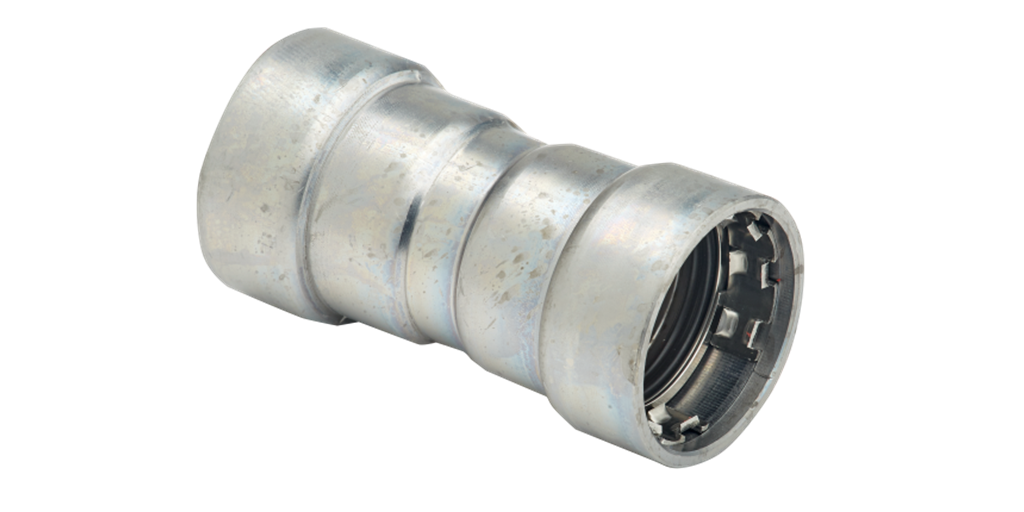

Thick walled press-fit fittings are made of a precision deformable body, containing an O-ring (elastomer) seal as well as a mechanical grip ring. Thick-walled (non-precision) tube is pushed into the fitting, and then a specially designed press-fit jaw, or crimping tool is used to compress the fitting body, seal and grip ring onto the tube, thereby creating the joint.

Thick walled press-fit fittings provide a permanent, heat-free jointing installation. These systems are sometimes referred to as crimped or socket fittings. These systems are designed to work with thick-walled traditional / non-precision tubes to satisfy higher operating pressures and service life requirements. Different O-ring (elastomer) materials may be used for different applications.

Typically these fittings are typically manufactured from carbon steel.

Carbon Steel Tubes

Carbon Steel Tubes