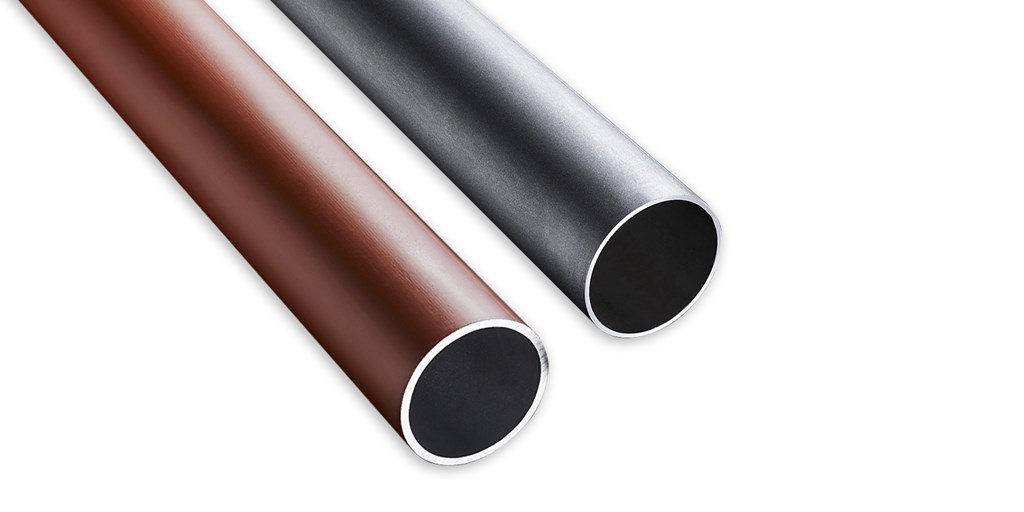

Carbon Steel, often referred to as mild steel, plain-carbon steel or low-carbon steel, is the most commonly used type of tube, because of its relatively low price, whilst providing toughness, strength and material properties that are suitable for a wide range of applications. Carbon steel is malleable and ductile, so easy to work with. Carbon steel tubes can be supplied in traditional wall thicknesses, typically referred to as Medium or Heavy weight or Sch (Schedule) sizes, or as a precision, thin walled product.

Tube can be supplied either as welded (hot-finished and cold-formed) or seamless (hot-finished), and the supply condition can influence how the tube performs in service. Hot-finished tubes have a range of technical advantages over cold-formed ones. Seamless may be able to take higher pressures and temperatures compared to welded. Carbon steel can be prone to corrosion, but, if the system conditions are suitably controlled, can have a life expectancy of many decades.

Connecting the system:

Carbon steel pipework can be welded together (directly or using flanges), or joined using a range of demountable (screwed, grooved, push-fit, couplings etc.) or non-demountable (press-fit etc.) fittings, each one having their own range of features and benefits, as well as possible application limitations.